- This topic is empty.

-

AuthorPosts

-

2025-11-28 at 6:37 pm #65022

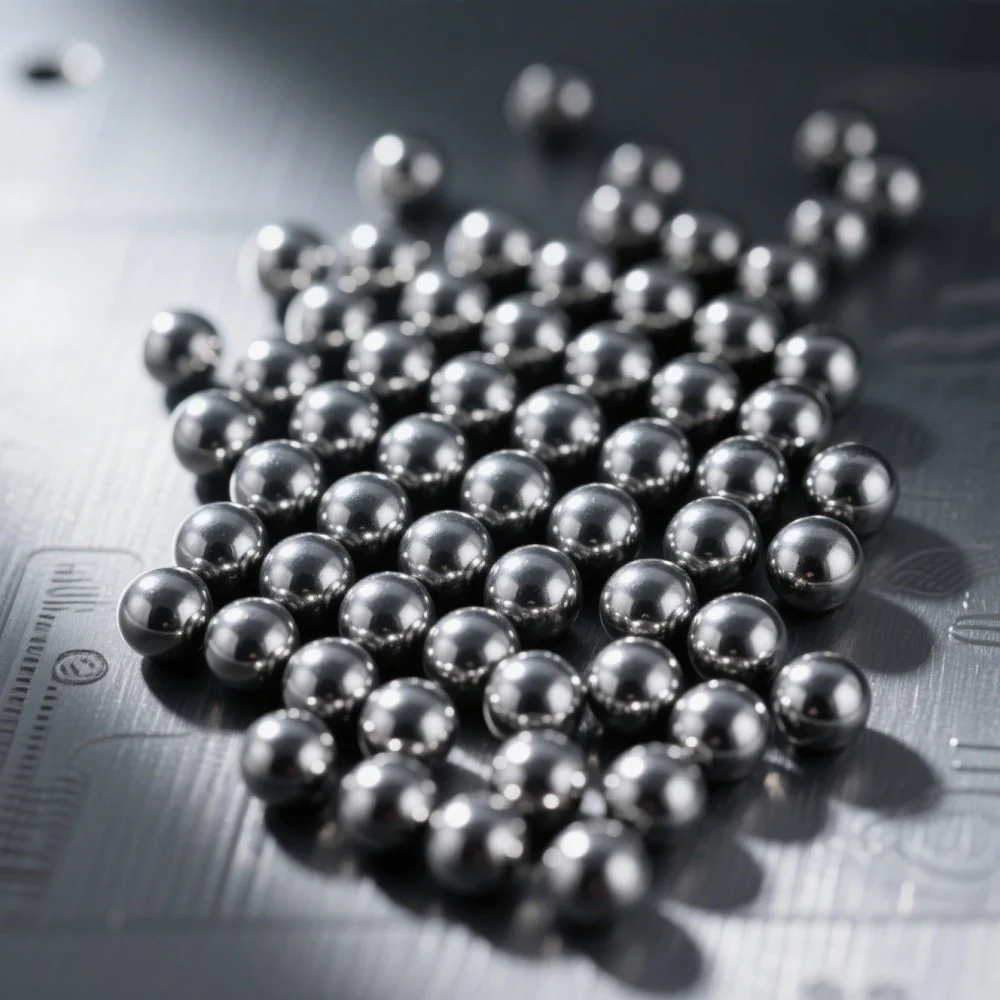

As the global machinery industry accelerates toward higher precision, longer service life, and stricter reliability requirements, the GCr15 bearing steel ball market is undergoing profound changes. In this blog post, Changzhou Eurasian, as high performance steel ball exporter, will share current market trends and changes in customer demand for GCr15 bearing steel balls for sale.

Rising Demand Trends in the GCr15 Bearing Steel Ball Market

In recent years, the global bearing industry has expanded rapidly, directly driving growth in the GCr15 bearing steel ball market. As the core rolling component of ball bearings, steel balls must meet extremely high standards for hardness, wear resistance, precision, and noise control. GCr15—also known as AISI 52100, SUJ2, or 100Cr6—remains the mainstream material due to its balanced chromium content, strong load-bearing capacity, uniform hardness, and exceptional fatigue life.

According to industry research data, the global bearing steel ball market reached 16.735 billion RMB in 2024 and is expected to grow to 26.181 billion RMB by 2030, with a 7.74% CAGR. China alone accounted for over 39.21 billion RMB in 2024, indicating its role as both a manufacturing hub and a major consumer market.

Evolving Customer Needs for High Precision GCr15 Steel Balls

As downstream sectors shift toward intelligent manufacturing and high-efficiency machinery, customers now demand higher precision, longer lifespan, and better consistency in GCr15 steel balls. Industries such as automotive, machine tools, aerospace, wind energy, and home appliances have raised performance standards across multiple dimensions:

-

Tighter dimensional tolerances (G10 to G3 levels)

-

Lower rotational noise for EV motors and high-speed spindles

-

Greater fatigue resistance for long-running industrial equipment

-

Improved surface roughness and roundness uniformity

-

Stronger corrosion resistance for challenging environments

To meet these expectations, advanced steel ball producers must refine heat treatment, cold heading, quenching, strengthening, and fine-grinding processes—areas in which Changzhou Eurasian Steel Ball Co., Ltd continues to enhance manufacturing capability.

Market Shift Toward Precision: Why High-End GCr15 Steel Balls Are Rising

The market is witnessing a clear structural upgrade: high-end precision steel balls are gaining market share, while low-end, low-precision products face increasing saturation.

Several factors are driving this transition:

1. Higher Technical Barriers in High-End Manufacturing

Producing GCr15 steel balls for critical bearings involves:

-

Highly controlled grinding fluid management

-

Precise heat-treatment cycles

-

Strengthening technologies to improve fatigue performance

-

Sophisticated inspection systems (roundness, hardness, surface defects)

Only manufacturers with long-term R&D investment can reliably achieve G3-level precision. This reduces the number of qualified suppliers and increases concentration in the premium market.

2. Long Certification Cycles

High-end customers, especially in aerospace and automotive sectors, require supplier certification periods of 2–3 years. This slows new market entry and increases the value of existing certified suppliers.

3. Rapid Growth in High-Performance Equipment

Wind turbines, EV drivetrains, robotics, and CNC machines are all expanding markets that rely heavily on precision bearings and, consequently, premium GCr15 steel balls.

As a result, demand is gradually consolidating toward technologically advanced producers capable of stable mass production—creating strong opportunities for companies with deep technical foundations.

Market Segmentation: Types and Demand Patterns for GCr15 Steel Balls

To better understand customer requirements, the GCr15 steel ball market can be divided by size, application, and region.

Size-Based Demand for GCr15 Bearing Steel Ball Products

According to recent market observations, small-sized bearing steel balls dominate global consumption due to their extensive use in household appliances, micro motors, small automotive bearings, and consumer electronics.

-

Small size: Largest market share in 2023; widely used in compact bearings

-

Medium size: Growing demand in industrial machinery and vehicle components

-

Large size: Stable growth driven by wind power, heavy engineering machinery, mining equipment

Changzhou Eurasian Steel Ball Co., Ltd offers wide dimensional ranges to meet these diverse industrial requirements.

Application Trends in GCr15 Chrome Steel Ball Usage

Across various end-use industries, the automotive sector continues to generate the highest demand for GCr15 steel balls.

Key application segments include:

-

Automotive bearings (wheel hubs, transmissions, engines, electric motors)

-

Aerospace systems requiring high fatigue resistance

-

Machine tool spindles where ultra-low noise and high rotational accuracy are essential

-

Wind energy turbines that require large, durable bearing components

-

Household appliances with high-speed miniature bearings

Growth in new energy vehicles (NEVs) further accelerates demand for low-noise, high-precision GCr15 balls.

Regional Dynamics: Asia-Pacific Leads GCr15 Bearing Steel Ball Consumption

As of 2023, the Asia-Pacific region held the largest market share due to its strong manufacturing ecosystem, spanning automotive production, industrial machinery, consumer electronics, and appliance manufacturing.

China remains the world’s largest producer and consumer, with significant clustering in:

-

East China

-

South China

-

North China

-

Central China

These regions benefit from supportive industrial policies, well-developed supply chains, and advanced manufacturing technologies.

Challenges and Opportunities in the GCr15 Steel Ball Market

Despite steady growth, the industry also faces several challenges:

Technical Gaps in Mid-to-High-End Segments

Many manufacturers still lag behind international standards in:

-

Heat treatment uniformity

-

Grinding precision control

-

Automated inspection technology

This gap presents opportunities for technologically strong companies to differentiate themselves.

Increasing Customer Expectations

End users expect:

-

More consistent quality

-

Faster delivery

-

Lower defect rates

-

Better documentation traceability

Manufacturers capable of digital process control and strict quality management will gain a competitive edge.

Strategic Position of Changzhou Eurasian in the Evolving Market

As a specialized manufacturer deeply rooted in the GCr15 steel ball industry, Changzhou Eurasian Steel Ball Co., Ltd continues to adapt to these market shifts by:

-

Strengthening precision manufacturing techniques

-

Upgrading equipment for higher stability and consistency

-

Expanding high-end product lines for automotive, aerospace, and wind power sectors

-

Implementing rigorous quality management systems

-

Increasing automation to support large-scale stable production

These capabilities position the company to capture growing opportunities in both domestic and global markets.

Outlook for the GCr15 Bearing Steel Ball Industry

Looking ahead to 2030, the GCr15 steel ball industry will continue to evolve along several major directions:

✔ Demand for high-precision steel balls will accelerate

Driven by EVs, aerospace, robotics, and high-speed machinery.

✔ Market concentration will continue to rise

Only companies with strong R&D, stable mass production, and advanced process control will maintain long-term competitiveness.

✔ China will further expand its global influence

Improved production capacity and technological upgrades will boost international market share.

✔ Quality, reliability, and consistency will be the primary purchasing criteria

Customers will increasingly require traceability, durability, and compliance with international standards.

Conclusion

The global GCr15 bearing steel ball industry is entering a new stage characterized by higher precision and rapid market expansion. For leading suppliers such as Changzhou Eurasian Steel Ball Co., Ltd, the ability to meet evolving customer requirements—especially in high-end applications—will be the key to long-term success.

By focusing on technology, quality, and innovation, the company is well positioned to strengthen its presence in both domestic and international markets and to seize the opportunities presented by the next generation of precision manufacturing.

http://www.cnballs.cn

Changzhou Eurasian -

-

AuthorPosts

- You must be logged in to reply to this topic.