- This topic is empty.

-

AuthorPosts

-

2026-01-30 at 9:37 am #65532

Soda-Lime Glass Balls: Cost-Effective Solution for Standard Applications

Material Properties & Technical Specifications

Soda-lime glass balls represent the most economical option for applications where extreme thermal or chemical resistance is not required:

-

Density: 2.4 – 2.6 g/cm³

-

Hardness: 5.5 – 6.5 Mohs (suitable for moderate-wear environments)

-

Thermal Expansion Coefficient: ~9 × 10⁻⁶/K

-

Available Precision Grades: G10 to G1000 per DIN 5401 / ISO 3290 standards

-

Chemical Resistance: Moderate (not recommended for strong acids/bases)

Primary Industrial Applications

Fluid Control Systems

-

Check valve components in water treatment systems

-

Flow regulation in pneumatic actuators

-

Dispensing valves for cosmetic and beverage industries

Agitation & Mixing

-

Stirring balls in paint and coating formulations

-

Pharmaceutical suspension mixers (non-GMP applications)

-

Laboratory media preparation

Filling & Leveling Media

-

Weight compensation in measuring instruments

-

Bulk filling in packaging applications

-

Acoustic dampening materials

Cost-Benefit Analysis for Bulk Procurement

For purchasing managers evaluating wholesale orders:

-

Price Advantage: 40-60% lower than borosilicate for equivalent precision grades

-

Minimum Order Quantity: 10,000 pieces for custom specifications

-

Lead Time: 15-20 days for standard G100-G500 grades

-

Customization Options: Black, blue, yellow, pink color variants available with density customization from 2.35 to 2.70 g/cm³

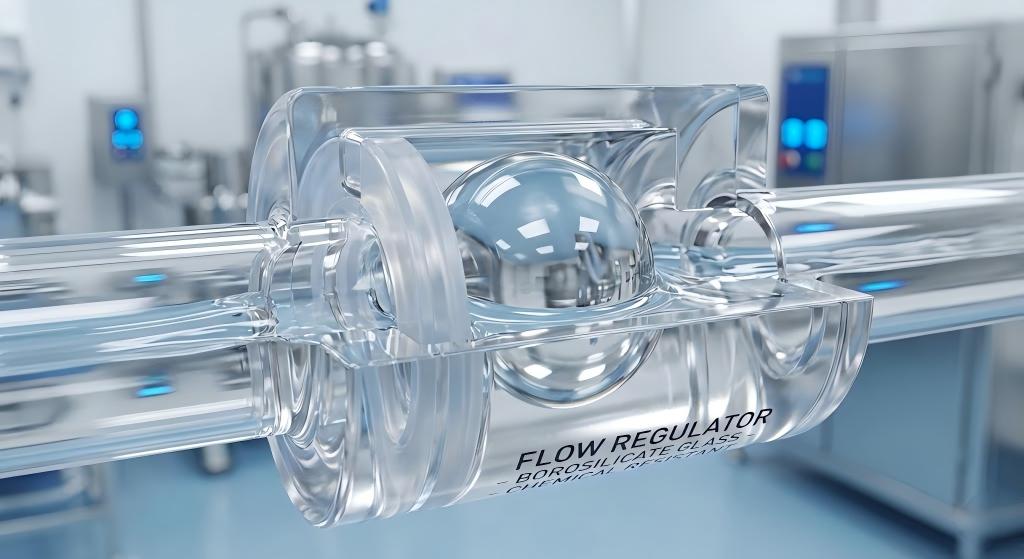

Borosilicate Glass Balls: Premium Performance for Demanding Environments

Advanced Material Characteristics

Borosilicate glass balls deliver superior thermal and chemical stability for critical applications:

-

Density: ~2.2 g/cm³ (lighter than soda-lime, reducing wear on mating surfaces)

-

Hardness: 6 – 7 Mohs

-

Thermal Expansion Coefficient: ~3.3 × 10⁻⁶/K (70% lower than soda-lime)

-

Thermal Shock Resistance: Withstands rapid temperature changes up to 165°C differential

-

Chemical Durability: Excellent resistance to acids, alkalis, and organic solvents

-

Available Precision Grades: G3 to G500 (ultra-high precision capability)

Critical Application Sectors

Medical & Pharmaceutical Manufacturing

-

Sterile fluid control valves in bioreactors

-

High-purity liquid dispensing systems (FDA GMPC compliant)

-

Autoclavable mixing balls for pharmaceutical suspensions

Chemical Processing Equipment

-

Corrosive fluid check valves (hydrochloric acid, sulfuric acid environments)

-

High-temperature reactor components

-

Solvent-resistant sealing elements

Laboratory & Scientific Instrumentation

-

Precision liquid chromatography components

-

Analytical instrument flow regulators

-

Research-grade mixing applications

Food & Beverage Industry

-

High-temperature pasteurization equipment

-

CIP (Clean-in-Place) system components

-

Hygienic valve assemblies per 3-A Sanitary Standards

Technical Advantages for Engineers

The 3.3 × 10⁻⁶/K thermal expansion coefficient provides three critical benefits:

-

Dimensional Stability: Maintains ±0.5 μm tolerance across 20-150°C operating range

-

Seal Integrity: Prevents leakage in cycling thermal conditions

-

Extended Service Life: Reduces stress-induced microcracking in valve seats

http://www.cnballs.cn

Changzhou Eurasian -

-

AuthorPosts

- You must be logged in to reply to this topic.