- This topic is empty.

-

AuthorPosts

-

2025-12-05 at 7:58 pm #65105

Urban infrastructure has evolved significantly over the past decades, driven by higher safety standards, greater environmental expectations, and the need for materials that outperform traditional iron and steel components. As cities expand and transportation networks grow, drainage systems—though often overlooked—play a crucial role in maintaining safe, functional public environments. Trench covers and rain grates must endure constant foot traffic, vehicle loads, weather changes, and corrosive environments.

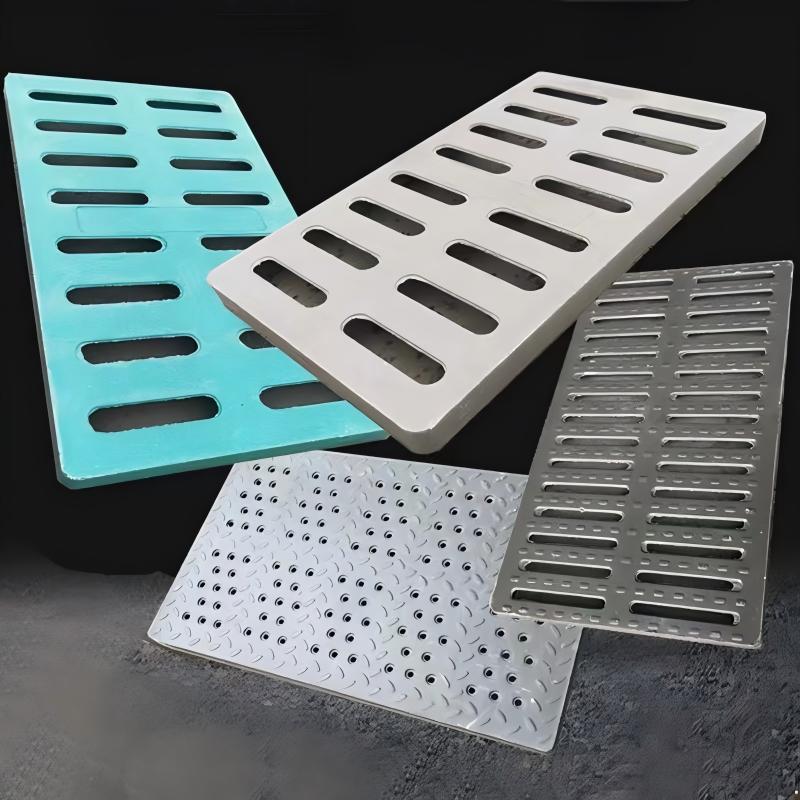

To address the limitations of older materials, many municipalities and engineering firms are transitioning toward Composite Resin Trench Covers, also known as Compound Rain Grates. These covers are engineered to deliver high durability, reduced maintenance, and long-term performance across a range of applications.

Based on New Line’s experience as a leading manhole cover and infrastructure solution provider, this article explores the structure, features, performance advantages, and field applications of composite resin trench covers used in modern municipal and commercial engineering projects.

1. What Is a Composite Resin Trench Cover?

A composite resin trench cover is a drainage component designed to cover open trenches, channels, and rainwater systems. Unlike cast iron or steel covers, composite covers are manufactured using reinforced resin materials that combine strength, corrosion resistance, and stability.

These covers come in specifications defined by the engineering parameter table and are commonly available in green and gray, allowing them to blend with both natural landscapes and urban settings.

Composite resin has become a preferred material for a variety of reasons:

-

Lightweight compared to iron

-

High mechanical strength

-

Corrosion and rust resistance

-

Stable performance at high temperatures

-

Low electrical conductivity

-

Reduced theft risk due to non-metallic composition

These characteristics make composite trench covers suitable for long-term use in demanding environments.

2. Key Material Advantages: Corrosion Resistance and Heat Resistance

One of the primary reasons engineers choose composite resin trench covers is their ability to resist environmental degradation.

Corrosion Resistance

Unlike traditional metal covers, composite resin does not rust, oxidize, or weaken when exposed to:

-

Moisture and rain

-

Road salts

-

Industrial pollutants

-

Chemicals used in parks or cleaning systems

This resistance significantly reduces maintenance costs over the lifespan of the product.

High Temperature Resistance

Trench covers in public and industrial settings often face:

-

Hot pavement surfaces

-

Direct sunlight

-

Heat emitted from underground cables or pipelines

Composite resin materials maintain structural integrity and operational stability under high temperatures, helping prevent deformation, cracking, or premature aging.

3. Strong Performance in High-Traffic Environments

Whether installed in a busy municipal road or a park walkway, trench covers must handle constant loading stress.

Composite resin trench covers are engineered to withstand:

-

Pedestrian loads

-

Bicycle traffic

-

Light vehicle traffic in parking areas

-

Maintenance vehicle access where applicable

Their structural reinforcement ensures load distribution, reducing the risk of breakage. The non-metallic finish also provides a non-slip surface, enhancing safety in wet weather.

4. A Lightweight Yet Strong Alternative to Metal Covers

Traditional cast iron covers are heavy, difficult to transport, and require machinery or multiple workers for installation. Composite resin trench covers solve these operational inefficiencies.

Benefits of reduced weight include:

-

Faster installation

-

Lower labor intensity

-

Safer manual handling

-

Simplified maintenance operations

This is especially useful for municipal departments and contractors who routinely install or inspect underground utilities.

Despite being lighter, composite covers maintain comparable compressive and flexural strength, ensuring reliable performance without sacrificing safety.

5. Reduced Theft Risk Due to Non-Metallic Construction

Metal covers historically face the risk of theft due to scrap metal value. Stolen trench covers create hazardous open trenches, increasing safety risks for pedestrians, cyclists, and vehicles.

Composite resin trench covers eliminate this problem entirely because they contain no scrap-metal value. Municipalities and industrial parks benefit from reduced replacement costs and enhanced public safety.

6. Versatile Use Across Public and Commercial Infrastructure

The wide applicability of composite resin trench covers makes them suitable for numerous environments, including:

-

Square pedestrian streets

-

Municipal roads

-

Urban parks and green belts

-

Highways

-

Parking lots

-

Industrial zones

-

Residential communities

These covers integrate well with different surface finishes such as concrete pathways, asphalt roads, paving stones, and landscaped areas.

The ability to withstand environmental exposure while maintaining appearance makes composite covers a practical choice for visible public infrastructure.

7. Supported by New Line’s Decades of Engineering Experience

New Line is recognized as a leader in manhole covers, road ironwork, and infrastructure solutions. With more than ten decades of industry experience, the company has developed a strong reputation for:

-

Technical innovation

-

High-quality product development

-

Customized engineering solutions

-

Market-leading material advancements

The company follows a people-oriented, safety-focused production philosophy. It implements modern safety systems and strict quality controls to ensure stable product performance and long service life.

Some of New Line’s application cases include:

-

Urban municipal road networks

-

Residential district drainage systems

-

Industrial park infrastructure

-

City squares and recreational parks

-

Municipal pipeline networks

This depth of industry involvement ensures that the composite resin trench covers are engineered for real-world conditions.

8. Sustainability and Reduced Environmental Impact

Composite resin materials contribute to reducing environmental impact in several ways:

-

Lower carbon footprint compared to metal foundry operations

-

No metal mining or smelting required

-

Longer service life reduces replacement frequency

-

Corrosion resistance eliminates pollution from rust contamination

-

Lightweight design reduces fuel and transport emissions

New Line integrates these environmental considerations into its product strategy, aligning engineering requirements with long-term sustainability goals.

9. Practical Considerations: Installation, Maintenance, and Lifespan

Composite resin trench covers provide advantages beyond performance. Their practicality in daily operations makes them a preferred solution for municipal engineering teams.

Installation Benefits

-

One- or two-person installation possible

-

No heavy machinery required

-

Lower risk of manual injuries

Maintenance Benefits

-

No rust removal

-

No anti-corrosion coating required

-

Easy inspection access

Long Lifespan

-

Resistant to environmental aging

-

Stable performance across seasons

-

Reliable under repeated loading conditions

These qualities ensure cost-effective and long-term operation of drainage systems.

10. A Reliable Choice for Modern City Development

As urban environments demand more durable, safer, and more environmentally responsible materials, composite resin trench covers offer a strong alternative to traditional iron covers. Their corrosion resistance, temperature stability, safety features, and practical handling advantages align well with modern infrastructure needs.

Backed by New Line’s century-long expertise, the Composite Resin Trench Cover provides engineers, contractors, and municipal departments with a robust, low-maintenance solution for long-term drainage and trench protection.

http://www.cnnewline.com

New Line -

-

AuthorPosts

- You must be logged in to reply to this topic.