- This topic is empty.

-

AuthorPosts

-

2025-12-02 at 6:17 pm #65054

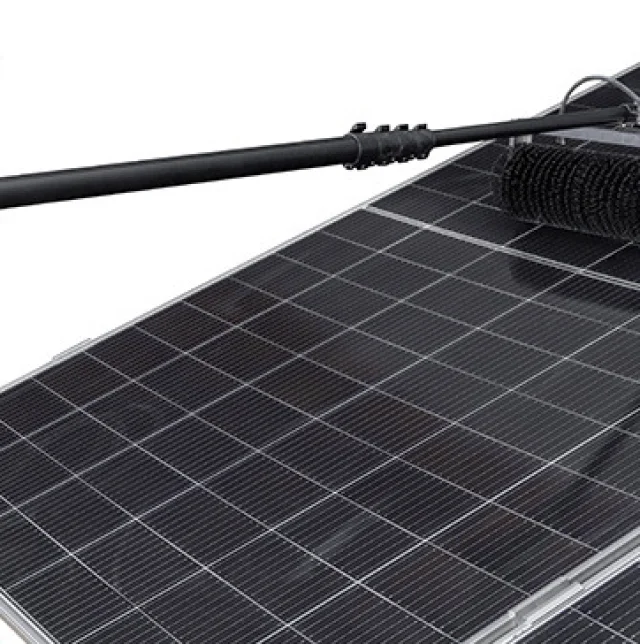

Solar panels rely on maximum sunlight exposure to deliver optimal output, yet dust, bird droppings, industrial residues, and accumulated debris gradually reduce energy generation. A solar rooftop cleaning roller brush offers a practical, efficient, and cost-effective way to maintain photovoltaic surfaces. Designed for routine cleaning schedules on residential rooftops, expansive commercial sites, and high-capacity industrial arrays, this tool ensures panels remain clean without causing damage.

The following article provides a comprehensive, 1500-word exploration of how roller brush systems work, their structural advantages, application scenarios, and how they support long-term solar asset performance.

Understanding the Solar Rooftop Cleaning Roller Brush System

A solar rooftop cleaning roller brush system is engineered to deliver precise, stable, and controlled cleaning for solar modules installed on rooftops or large-scale ground arrays. Unlike manual rags or basic water flushing, roller brushes apply consistent pressure across the panel surface, ensuring uniform cleaning.

Modern systems—such as the Solar Panel Cleaning Roller Brush described—integrate both wet and dry cleaning modes, allowing users to adapt to seasonal needs, geographic conditions, and operational constraints.

How Solar Panel Cleaning Roller Brush Improves Energy Output

When dirt accumulates on photovoltaic surfaces, energy loss can reach 5–30% depending on environment and climate. A solar panel cleaning roller brush minimizes these losses by:

-

Removing micro-dust and fine particles that reduce light absorption

-

Cleaning stubborn stains without scratching tempered glass

-

Allowing routine maintenance that keeps cells exposed to maximum sunlight

-

Supporting dry cleaning in water-limited regions

-

Increasing panel lifespan through gentle but effective cleaning motion

The result is stable, predictable, and higher power performance throughout the year.

Key Structural Features of Solar Rooftop Cleaning Brush

The efficiency of any cleaning tool depends on design. A solar cleaning roller brush system typically includes:

High-Strength Brush Fibers

The bristles are made from wear-resistant, UV-resistant materials that maintain shape over time. Their softness prevents surface scratches while still generating sufficient friction to remove grime.

Lightweight and Balanced Roller Body

To reduce operator fatigue, the frame and drum are commonly built using aluminum alloy or engineering-grade composites. This improves maneuverability, especially on large rooftops.

Wet and Dry Cleaning Compatibility

Some solar rooftop cleaning roller brushes integrate water spray lines or portable water-feeding systems. This dual-mode flexibility makes the equipment suitable for dusty environments and wet cleaning requirements.

Telescopic or Adjustable Handles

For rooftop installations, height and angle adjustments are crucial. Telescopic rods help users clean panels located far, high, or in tight spaces.

Energy-Efficient Power Drive

Professional-grade models include electric or battery-powered rollers that deliver steady rotational force, reducing manual effort and ensuring uniform brushing.

Why Rooftop Solar Cleaning Requires Specialized Roller Brushes

Avoiding Scratches and Micro-Damage

Solar panels feature anti-reflective coatings that improve light absorption. Using non-specialized cleaning tools risks damaging this coating. A solar rooftop roller brush is purpose-built to clean without abrasion.

Maintaining Safety on Elevated Surfaces

Rooftop work involves slopes, height differences, and weather exposure. Roller brushes provide extended reach and controlled maneuverability, reducing the need to step directly on panels.

Managing Large Panel Arrays Efficiently

Commercial and industrial solar farms often contain hundreds of modules. Roller systems offer continuous, wide-surface cleaning that greatly reduces labor time compared to cloth cleaning.

Applications Across Residential, Commercial, and Industrial Settings

Residential Solar Rooftop Maintenance

Homeowners benefit from compact solar rooftop cleaning roller brushes that simplify periodic cleaning. Because dust accumulation is often light but frequent, easy-to-operate tools are ideal.

Commercial Photovoltaic Facilities

Shopping malls, office buildings, and warehouses with mid-sized arrays require tools that offer higher capacity and uniform cleaning. Roller brushes maintain long-term energy stability for business operations.

Industrial and Utility-Scale Solar Plants

Large arrays in industrial zones face heavy pollution from chemicals, soot, and machinery emissions. Professional solar cleaning roller brush systems deliver fast coverage and deep cleaning solutions to maintain energy yield.

Advantages of Solar Rooftop Cleaning Roller Brush

A solar rooftop cleaning brush system provides several operational and economic advantages:

Consistent Cleaning Quality

Roller pressure remains even across the surface, avoiding patchy cleaning results.

Labor Efficiency

Operators spend less time per panel, lowering maintenance costs for large installations.

Reduced Water Use

Dry brushing capability is valuable in regions with water scarcity. Wet mode can be activated only when needed.

Long-Term Maintenance Support

Regular cleaning prevents long-term buildup that can cause corrosion, hotspot formation, and reduced panel efficiency.

User-Friendly Operation

Professional models balance power with ease of use, enabling both skilled technicians and first-time users to operate them safely.

Wet vs. Dry Cleaning with Solar Panel Roller Brushes

The ability to alternate between wet and dry cleaning sets roller brushes apart from traditional tools.

Dry Cleaning

Ideal for:

-

High-dust environments

-

Daily or weekly maintenance

-

Situations with limited water availability

Dry brushing quickly removes loose materials without leaving streaks.

Wet Cleaning

Best for:

-

Oil residues

-

Bird droppings

-

Sticky or baked-on pollutants

-

Industrial soot

Water spray combined with rotation loosens and removes stubborn contaminants.

Operators can seamlessly switch modes depending on panel condition.

Choosing the Right Solar Cleaning Roller Brush for Your Needs

To optimize cleaning efficiency, consider the following selection criteria:

Cleaning Width and Roller Length

Wider rollers cover more surface area per pass, reducing labor for large installations. Compact rollers offer better control for rooftop edges and narrow spaces.

Power Options

Battery-powered, electric, or manual options exist. Battery-powered rollers offer the best balance between mobility and force output.

Handle Length and Adjustability

For rooftop applications, ensure the handle can extend to reach distant panels without overstretching.

Material Durability

Brush bristles, bearings, and roller frame materials should resist UV exposure, temperature fluctuations, and repeated use.

Water Integration

If needed, choose a model with a built-in water supply line or compatible external connection.

Maintenance Practices for Long-Term Roller Brush Performance

A solar rooftop cleaning roller brush system continues to deliver consistent cleaning only with proper maintenance:

-

Rinse bristles thoroughly after each use to remove fine dust

-

Store the brush in a dry area to prevent mold or bristle deformation

-

Inspect power systems, batteries, or water lines regularly

-

Replace worn bristles promptly to prevent panel damage

-

Avoid excessive pressure during use, allowing the roller system to perform naturally

These simple steps extend tool lifespan and maintain the safety of solar panels.

Role of Solar Panel Cleaning Roller Brushes in Energy Management

As solar adoption increases globally, maintenance strategies are becoming more standardized. The Solar Panel Cleaning Roller Brush, with its optimized blend of power, precision, and user-friendliness, supports long-term asset performance.

Its engineering—balancing rotational speed, ergonomic design, and wet/dry flexibility—makes it suitable for diversified environmental conditions and panel types. Whether used for monthly residential cleaning or daily industrial maintenance, roller brush systems ensure that solar installations remain reliable and productive.

Final Thoughts

Keeping solar panels clean directly affects energy output, operational stability, and long-term ROI. A solar rooftop cleaning roller brush provides an efficient, professional-grade, and easy-to-use solution that supports all scales of solar installations.

By integrating specialized materials, ergonomic mechanisms, and versatile cleaning modes, these brushes simplify maintenance and help users protect their solar investments. For anyone seeking a structured, safe, and effective cleaning approach, the roller brush system stands as a dependable choice for modern solar management.

-

-

AuthorPosts

- You must be logged in to reply to this topic.