- This topic is empty.

-

AuthorPosts

-

2025-12-29 at 1:55 pm #65307

Choosing the right elevator traction system is a critical decision that directly impacts a building’s safety, energy efficiency, passenger comfort, and long-term operating costs. Whether you are developing a residential complex, a commercial office tower, a hospital, or a high-rise mixed-use building, the traction system you select will define how reliably and efficiently your elevators perform for decades.

With rapid advancements in elevator technology, today’s elevator traction systems offer a wide range of configurations, from traditional geared systems to advanced gearless and machine-room-less (MRL) solutions. This guide provides a comprehensive overview of how to evaluate your building’s needs and select the most suitable elevator traction system with confidence.

1. Understanding Elevator Traction Systems

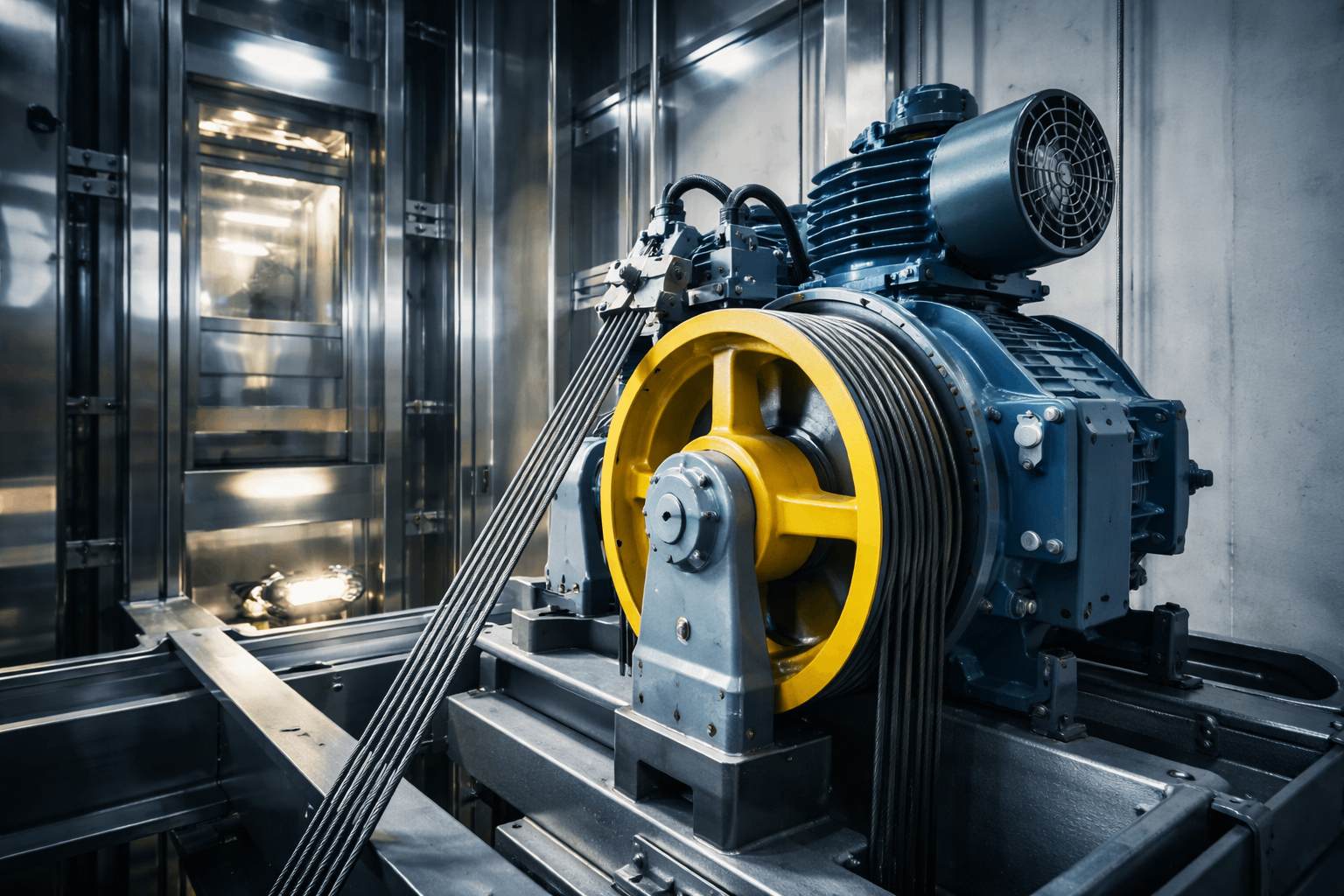

An elevator traction system operates using a motor-driven sheave (pulley), steel wire ropes or belts, and a counterweight that balances the elevator car. As the motor rotates the sheave, friction between the ropes and the sheave moves the car up or down.

Compared with hydraulic elevators, traction elevators are known for:

-

Higher travel speeds

-

Better energy efficiency

-

Smoother ride quality

-

Greater suitability for mid-rise and high-rise buildings

Before choosing a specific system, it is essential to understand the main traction system types available on the market.

2. Types of Elevator Traction Systems

2.1 Geared Traction Systems

Geared traction elevators use a gearbox between the motor and the sheave to control speed and torque.

Advantages:

-

Lower initial equipment cost

-

Proven and widely used technology

-

Suitable for mid-rise buildings

Limitations:

-

Lower energy efficiency

-

More mechanical wear due to gears

-

Higher maintenance requirements

Geared traction systems are often selected for older buildings or projects with tighter upfront budgets.

2.2 Gearless Traction Systems

Gearless elevator traction systems connect the motor directly to the sheave, eliminating the gearbox.

Advantages:

-

Superior energy efficiency

-

Higher speed capability

-

Reduced noise and vibration

-

Longer service life

Limitations:

-

Higher initial investment

-

Requires precise installation and control systems

Gearless traction systems are the preferred choice for high-rise buildings, premium commercial projects, and applications where performance and ride comfort are critical.

2.3 Machine Room-Less (MRL) Traction Systems

MRL traction systems integrate compact traction machines within the hoistway, removing the need for a traditional machine room.

Advantages:

-

Space-saving design

-

Reduced construction costs

-

Lower energy consumption

-

Ideal for modern urban buildings

Limitations:

-

Limited load and speed range compared to full machine-room systems

-

Maintenance access can be more complex

MRL elevator traction systems are widely used in residential, hotel, and mid-rise commercial buildings.

3. Key Factors to Consider When Choosing an Elevator Traction System

Selecting the right elevator traction system requires balancing multiple technical and operational factors. Below are the most important considerations.

3.1 Building Height and Number of Floors

Building height is one of the most decisive factors.

-

Low-rise buildings (2–5 floors): MRL or geared traction systems are usually sufficient.

-

Mid-rise buildings (6–15 floors): Gearless or high-efficiency geared traction systems are recommended.

-

High-rise buildings (16+ floors): Gearless traction systems are the industry standard due to their speed, efficiency, and reliability.

The greater the travel height, the more important motor efficiency, rope technology, and control precision become.

3.2 Elevator Speed Requirements

Different building types require different elevator speeds:

-

Residential buildings: moderate speeds focused on comfort

-

Office buildings: higher speeds to handle peak traffic

-

Hospitals: smooth acceleration and deceleration for patient safety

-

Hotels: quiet operation and premium ride quality

Gearless elevator traction systems excel in applications requiring high speed and smooth performance.

3.3 Load Capacity and Traffic Flow

Passenger capacity and traffic patterns should be carefully analyzed:

-

Peak-hour traffic volume

-

Average passenger load

-

Special requirements (freight, hospital beds, service elevators)

Buildings with heavy traffic benefit from traction systems designed for frequent starts, stops, and high-duty cycles.

3.4 Energy Efficiency and Sustainability Goals

Energy efficiency is now a core consideration, especially for green building certifications.

Modern elevator traction systems can include:

-

Permanent magnet synchronous motors

-

Regenerative drives that return energy to the grid

-

Lightweight suspension ropes or belts

These technologies significantly reduce power consumption and operating costs over time.

3.5 Space and Architectural Constraints

Available space can limit system selection:

-

Limited rooftop space favors MRL traction systems

-

Tight shafts require compact traction machines

-

Architectural aesthetics may restrict machine room placement

Early coordination between elevator engineers and architects is crucial to avoid costly redesigns.

3.6 Noise and Ride Comfort

Noise, vibration, and ride smoothness are particularly important in:

-

Residential buildings

-

Hotels

-

Hospitals

Gearless traction systems generally provide quieter operation and superior ride comfort due to fewer moving parts and precise motor control.

3.7 Maintenance and Lifecycle Costs

Initial purchase price is only part of the total cost. Consider:

-

Routine maintenance frequency

-

Spare parts availability

-

Expected service life

-

Downtime risks

While gearless elevator traction systems cost more upfront, they often deliver lower lifetime costs due to reduced maintenance and higher efficiency.

4. Safety Standards and Compliance

Any elevator traction system must comply with local and international safety standards, such as:

-

EN 81

-

ASME A17.1 / CSA B44

-

ISO standards

Ensure the system includes:

-

Reliable braking mechanisms

-

Overspeed governors

-

Redundant safety circuits

-

Emergency rescue devices

Choosing certified equipment from reputable manufacturers minimizes safety risks and regulatory issues.

5. Matching Traction Systems to Building Types

Residential Buildings

-

Focus on comfort, noise reduction, and energy efficiency

-

MRL or gearless traction systems are commonly used

Commercial Office Buildings

-

Emphasis on speed, traffic handling, and reliability

-

Gearless traction systems with advanced control systems are ideal

Hospitals

-

Smooth motion, precision leveling, and reliability

-

Gearless systems with specialized control logic are preferred

Hotels

-

Quiet operation and premium ride experience

-

Gearless or high-end MRL traction systems

6. Future-Proofing Your Elevator System

When choosing an elevator traction system, consider long-term adaptability:

-

Compatibility with smart building systems

-

Remote monitoring and predictive maintenance

-

Energy-saving upgrades

-

Modernization potential

Future-ready traction systems help protect your investment as building technologies evolve.

7. Working with the Right Elevator Traction System Company

Selecting a reliable supplier is as important as choosing the system itself. Look for partners who offer:

-

Proven project experience

-

Custom engineering support

-

Compliance with international standards

-

Strong after-sales service and technical support

A professional supplier can help optimize system configuration based on your building’s specific requirements rather than offering a one-size-fits-all solution.

8. Final Thoughts

Choosing the right elevator traction system is a strategic decision that affects building performance, user experience, and operational efficiency for decades. By carefully evaluating building height, speed requirements, energy efficiency goals, space constraints, and lifecycle costs, developers and building owners can make informed choices that deliver long-term value.

Modern elevator traction systems provide flexible, efficient, and safe solutions for virtually every building type. Investing time in proper system selection and working with experienced professionals ensures your elevator system will operate reliably, efficiently, and comfortably well into the future

http://www.xinlinelevator.com

xinlinelevator -

-

AuthorPosts

- You must be logged in to reply to this topic.