- This topic is empty.

-

AuthorPosts

-

2025-12-22 at 3:53 pm #65196

In modern research and industrial laboratories, ultrasonic homogenizers have become indispensable tools for sample preparation, cell disruption, emulsification, and nanoparticle dispersion. However, choosing the best ultrasonic homogenizer for your lab is not a simple task. With a wide range of models, features, and performance levels available, making an informed decision requires careful consideration of your workflow, sample types, throughput goals, and budget. This comprehensive guide will help you navigate the selection process, understand critical specifications, and choose the ultrasonic homogenizer that best fits your laboratory needs.

1. Why Your Lab Needs an Ultrasonic Homogenizer

Ultrasonic homogenizers use high-frequency sound waves to create cavitation in liquid samples, generating intense micro‑scale energy that can break apart cells, reduce particle size, and create fine emulsions. Compared to traditional mechanical homogenization, ultrasonication offers several advantages:

-

Effective cell disruption: Ideal for lysing tough cells (e.g., bacteria, yeast, plant tissue) without harsh chemicals.

-

Fine particle size reduction: Produces uniform dispersions down to the nanoscale.

-

Versatile applications: From protein extraction and nanoparticle synthesis to degassing and emulsification.

-

Precise control: Adjustable amplitude, pulse mode, and processing time.

These benefits make ultrasonic homogenizers valuable for biotechnology, pharmaceuticals, materials science, food science, and environmental labs.

2. Key Factors to Consider

Before purchasing an ultrasonic homogenizer, evaluate several important factors that directly affect performance and suitability for your workflows.

2.1 Application Requirements

Start by defining the primary applications you expect the device to serve:

-

Cell lysis and extraction: If your work focuses on biological samples, look for models with precise amplitude control and cooling options to protect delicate biomolecules.

-

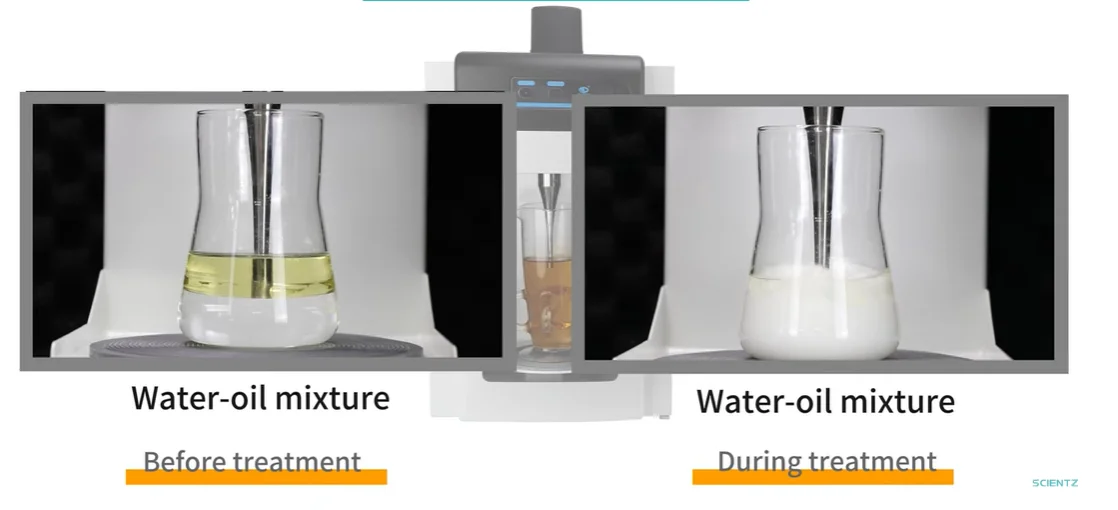

Emulsification and dispersion: Labs working with oil‑water systems or nanoparticle suspensions need robust cavitation and efficient mixing capabilities.

-

Nanomaterial processing: High amplitude and reproducible energy delivery are key to achieving consistent nanoscale results.

-

Sample throughput: Large sample volumes or frequent processing may require higher power or multiple probes.

Understanding your use cases helps narrow down suitable models and configurations.

2.2 Power and Amplitude

Ultrasonic homogenizer performance is largely determined by power output (Wattage) and amplitude:

-

Power output reflects the total energy delivered. Higher wattage systems can handle larger volumes and more demanding applications.

-

Amplitude indicates the intensity of ultrasonic vibration at the probe tip. Adjustable amplitude helps optimize cavitation strength for different sample types.

For example, tough cell walls or viscous media may require higher amplitude settings, while delicate samples benefit from lower amplitude to avoid degradation.

2.3 Probe Size and Shape

The probe (or horn) connects the ultrasonic transducer to the sample and plays a crucial role in energy transfer. When choosing a probe:

-

Diameter matters: Larger probes process bigger volumes faster but require more power. Smaller probes are ideal for low‑volume precision work.

-

Material quality: Titanium or hard alloys improve durability and reduce wear.

-

Shape considerations: Flat or tapered probes influence cavitation patterns and efficiency.

Many manufacturers offer a range of probes to match different sample sizes, from microliter tubes to liter‑scale beakers.

2.4 Frequency and Mode Options

Ultrasonic homogenizers typically operate in the 20–40 kHz range. Lower frequencies (around 20 kHz) produce more intense cavitation, suitable for robust disruption and emulsification. Higher frequencies can be gentler, making them better for sensitive applications.

Other useful mode features include:

-

Pulse mode: Delivers bursts of ultrasonication to reduce heat buildup.

-

Continuous mode: Useful for larger volume processing.

-

Programmable settings: Allow precise control and reproducibility between runs.

Flexibility in frequency and mode enhances versatility across applications.

2.5 Sample Volume and Throughput

Workload size greatly influences your choice:

-

Low‑volume processing (µL–mL): Smaller bench‑top models with micro‑probes.

-

Medium volumes (tens–hundreds of mL): Mid‑range units with adjustable amplitudes and larger horns.

-

High‑volume processing ( liters): Industrial‑grade homogenizers with flow cells or multiple probes.

Be realistic about your throughput needs. Investing in an oversized system for occasional use may not be cost‑effective, while undersized systems can bottleneck your workflow.

2.6 Cooling and Temperature Control

Ultrasonication generates heat, especially at high amplitudes or long processing times. Heat can:

-

Denature proteins

-

Degrade nucleic acids

-

Alter sample composition

Look for systems that offer effective temperature control features:

-

Pulse mode to reduce heat accumulation

-

External cooling accessories (ice baths, chilled circulating systems)

-

Temperature monitoring and auto shutoff

Temperature management ensures sample integrity and reproducibility.

3. Ease of Use and Workflow Integration

Selecting an ultrasonic homogenizer should not only focus on performance specs but also usability:

3.1 User Interface and Controls

Modern systems feature intuitive touchscreens, digital displays, and programmable protocols. Benefits include:

-

Quick setup of amplitude, time, and pulse settings

-

Memory storage for repeatable workflows

-

Real‑time status monitoring

User‑friendly interfaces reduce training time and operator errors.

3.2 Maintenance and Cleaning

Choose models with easily removable and cleanable probes to prevent cross‑contamination between samples. Consider:

-

Autoclavable probe options

-

Simple access to worn components

-

Provider support for parts and servicing

Regular maintenance extends the life of your homogenizer and ensures consistent performance.

3.3 Safety Features

Ultrasonic equipment involves high energy and liquid handling. Good safety features include:

-

Protective enclosures or splash guards

-

Overheat protection

-

Automatic shutoff on fault detection

Ensuring operator safety is essential in any laboratory environment.

4. Budget and Total Cost of Ownership

Cost is always a practical concern. When budgeting, consider:

-

Initial purchase price – Depends on power, features, and brand.

-

Accessory costs – Probes, cooling systems, flow cells.

-

Maintenance and warranty – Long‑term support affects total cost.

-

Utility impact – Power usage and consumables.

Balancing performance with budget constraints ensures cost‑effective equipment investment.

5. Comparing Popular Homogenizer Types

Ultrasonic homogenizers are one of several homogenization technologies. For context, here’s how they compare with alternatives:

-

Mechanical homogenizers: Great for coarse disruption but less effective for nanoscale dispersion.

-

High‑pressure homogenizers: Excellent for emulsions at scale but can be expensive and complex.

-

Bead mills: Efficient for hard tissue disruption but involve consumable beads and more cleanup.

Ultrasonic homogenizers excel when precise control, fine dispersion, and versatile applications are needed.

6. Real‑World Selection Examples

Here are scenarios illustrating how to choose appropriately:

Example A: Microbiology Lab

A microbiology lab focused on bacterial protein extraction may prioritize:

-

Adjustable amplitude & pulse mode

-

Cooling accessories

-

Small probes for low volumes

Key features: Precision control, gentle temperature management.

Example B: Materials Science Lab

A lab synthesizing nanoparticles might require:

-

Higher power output

-

Larger probes for mid‑volume dispersion

-

Stable amplitude for repeatable results

Key features: High energy delivery, consistent sonication.

Example C: Food Science Applications

A food research group developing emulsions may want:

-

Flow‑through capability for larger samples

-

Robust construction for viscous liquids

-

Easy cleaning for frequent sample changes

Key features: High volume processing, easy maintenance.

7. Conclusion

Choosing the best ultrasonic homogenizer for your lab is a strategic decision that impacts research quality, workflow efficiency, and long‑term value. By assessing your specific application needs, sample types, throughput requirements, and operational preferences, you can select a system that delivers reliable performance and enhances experimental outcomes.

Whether you’re performing delicate cell lysis, nanoparticle dispersion, or large‑scale emulsification, the right ultrasonic homogenizer will empower your team with precision, versatility, and reproducibility. Prioritize intuitive controls, appropriate power ratings, effective cooling, and solid manufacturer support, and your investment will pay off in improved productivity and scientific excellence.

http://www.dscientz.com

dscientz -

-

AuthorPosts

- You must be logged in to reply to this topic.