- This topic is empty.

-

AuthorPosts

-

2025-10-29 at 2:44 pm #64814

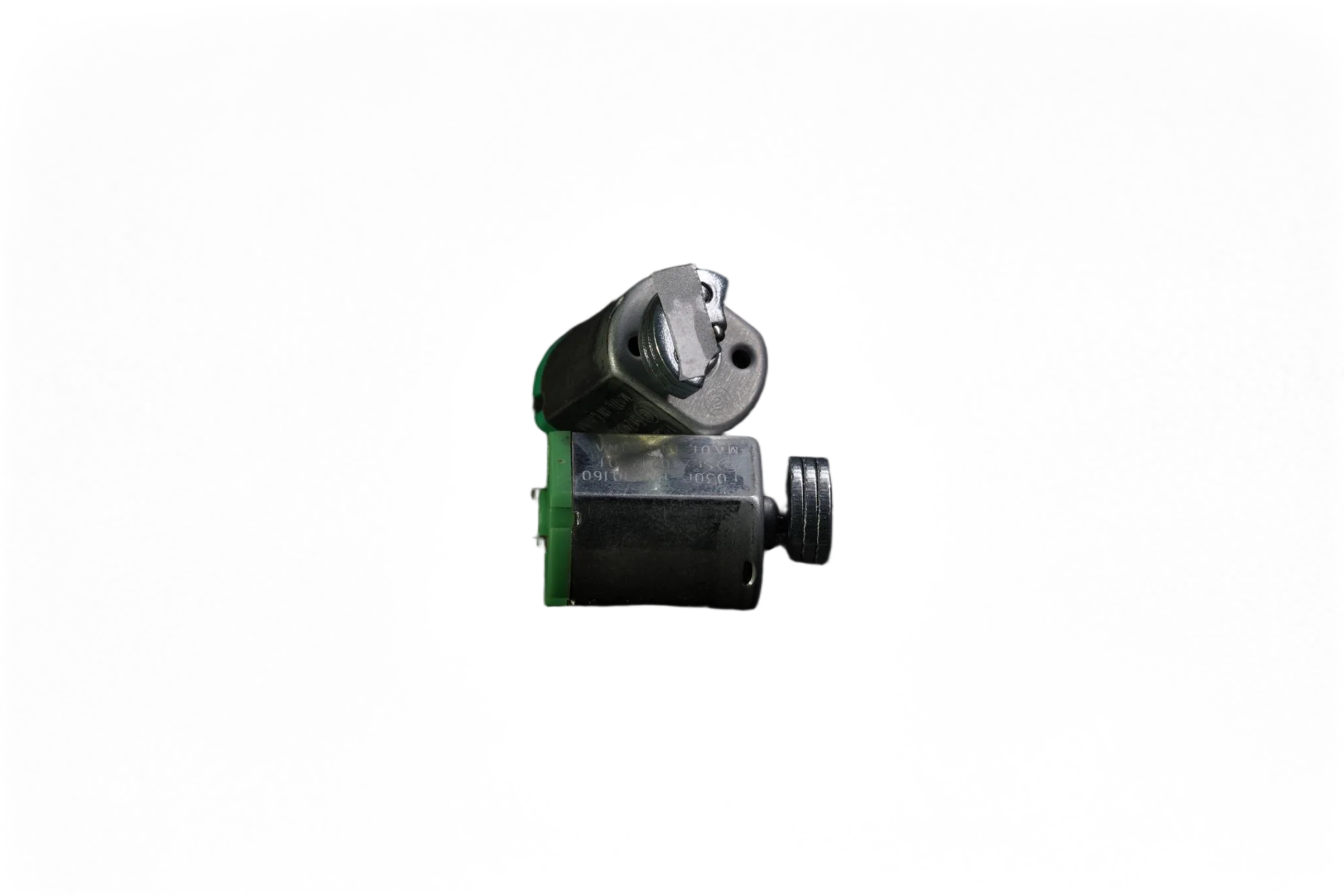

In the rapidly evolving world of office automation, the demand for compact, efficient, and reliable components has never been higher. Among these components, mini DC brushed motors play a pivotal role, driving devices from printers to automated filing systems. In this blog post, EcoMotor, a high-performance DC motor manufacturing factory, will share the features of mini DC brushed motor for office automation equipment, its advantages, etc.

Understanding Mini DC Brushed Motors for Office Automation

Mini DC brushed motors are small, versatile motors powered by direct current (DC) that utilize brushes to conduct electricity between stationary and rotating parts. These motors are widely recognized for their simplicity, cost-effectiveness, and reliable performance in low to medium power applications. In office automation, they are instrumental in enabling smooth operation in devices such as paper feeders, scanner drives, robotic arms, and automated document handling systems.

Key Features of Mini DC Brushed Motors in Office Equipment

When selecting a mini DC brushed motor for office automation, several critical features determine its suitability:

-

Compact Size and Lightweight Design – Their small footprint allows integration into tight spaces, essential for sleek and compact office machinery.

-

High Torque-to-Size Ratio – Despite their size, these motors provide sufficient torque to drive components like rollers, gears, and belts efficiently.

-

Simple Control Mechanism – Brushed motors are easily controlled using voltage variations or PWM (Pulse Width Modulation), making them ideal for precision applications.

-

Cost Efficiency – Compared to brushless alternatives, mini DC brushed motors offer a lower upfront cost, which is advantageous for high-volume office equipment production.

-

Maintenance Considerations – While brushes wear over time, regular inspection and replacement ensure consistent performance.

Applications in Office Automation Equipment

Mini DC brushed motors have a broad range of applications within office environments, enhancing both productivity and reliability:

Printer and Copier Systems

Printers and copiers require precise motion control for paper feeding, scanning, and printing mechanisms. Mini DC brushed motors provide the consistent torque and speed needed for rollers, belts, and fuser units, ensuring smooth operation without jams or misfeeds.

Automated Document Handling

Automated filing and sorting systems benefit from mini DC brushed motors for conveyor drives, sorting arms, and lift mechanisms. Their compact size allows seamless integration into machinery that must handle large volumes of documents efficiently.

Office Robotics

Emerging office robotics, including desktop assistants or mail-sorting robots, rely on precise motor control. Mini DC brushed motors deliver the balance between power and precision, enabling accurate movement in robotic arms or wheeled platforms.

Other Peripheral Devices

Beyond core machinery, peripherals like electronic staplers, label printers, and card dispensers utilize mini DC brushed motors for efficient and reliable motion, contributing to overall office automation.

Advantages Over Alternative Motor Types

While brushless DC motors and stepper motors are increasingly popular, mini DC brushed motors maintain advantages that make them indispensable in office automation:

-

Ease of Control – Unlike stepper motors that require complex drivers, brushed motors can be controlled with simple circuitry.

-

Immediate Torque Response – Brushed motors provide instant torque, suitable for devices requiring sudden starts or stops.

-

Lower Initial Cost – For equipment where high-speed efficiency or minimal maintenance is not critical, brushed motors offer significant cost savings.

Factors to Consider When Selecting a Mini DC Brushed Motor

To maximize performance and lifespan, several factors must be evaluated:

-

Voltage and Current Requirements – Ensuring compatibility with the office device’s power supply avoids performance degradation or overheating.

-

Torque and Speed Specifications – Correctly matching the motor’s torque and speed to the load ensures efficiency and longevity.

-

Duty Cycle – Understanding the motor’s operational cycle prevents premature wear from overuse in high-duty applications.

-

Noise Level – In office environments, quieter motors contribute to a more pleasant workspace. Selecting motors with reduced vibration and noise is often essential.

-

Maintenance Accessibility – Designs allowing easy brush replacement or motor servicing reduce downtime in office machinery.

Integration Best Practices

Proper integration of mini DC brushed motors enhances reliability and efficiency:

-

Use of Gearboxes – Gear reduction mechanisms optimize torque output for heavy loads while controlling speed.

-

Mounting and Alignment – Correct positioning reduces wear on bearings and brushes, minimizing maintenance.

-

Temperature Management – Ensuring adequate ventilation or heat dissipation prolongs motor life.

-

Electronic Protection – Incorporating current limiting or thermal cutoff circuits prevents damage from overloads.

Future Trends in Office Automation Motors

While brushless and stepper motors are gaining traction in certain high-performance applications, mini DC brushed motors continue to evolve. Improvements in materials, brush design, and miniaturization are extending their lifespan and efficiency. Additionally, hybrid motor systems are being developed to combine the benefits of brushed motors’ simplicity with advanced electronic controls, making them even more adaptable to modern office automation needs.

Conclusion

Mini DC brushed motors remain a cornerstone of office automation equipment due to their compact size, cost-effectiveness, and reliable performance. From printers to automated document handling and robotic peripherals, these motors deliver precise and consistent motion that drives productivity in modern offices. By understanding their features, applications, and integration strategies, manufacturers can optimize office machinery for efficiency, reliability, and long-term performance.

http://www.ecomotorhk.com

EcoMotor -

-

AuthorPosts

- You must be logged in to reply to this topic.